Our wide range of industrial knives

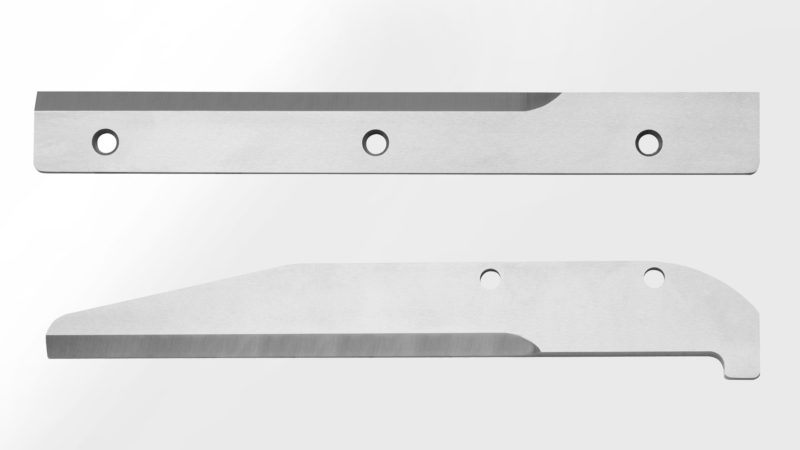

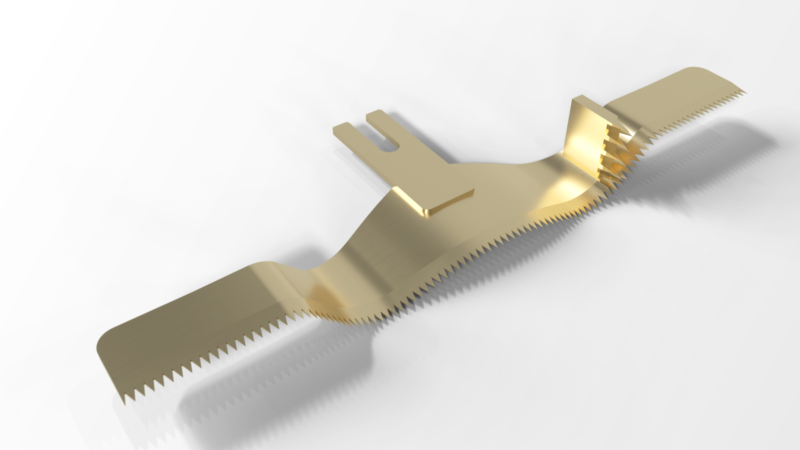

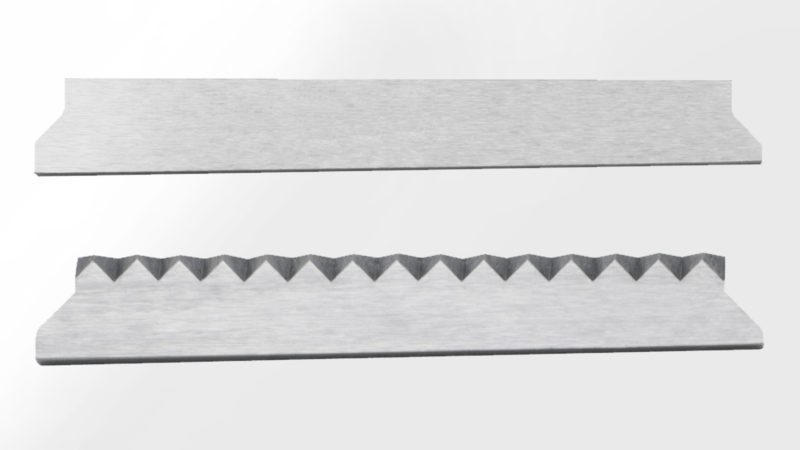

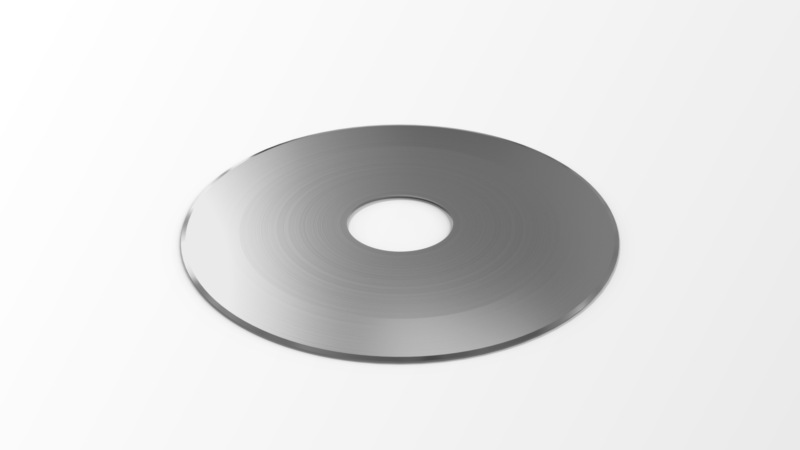

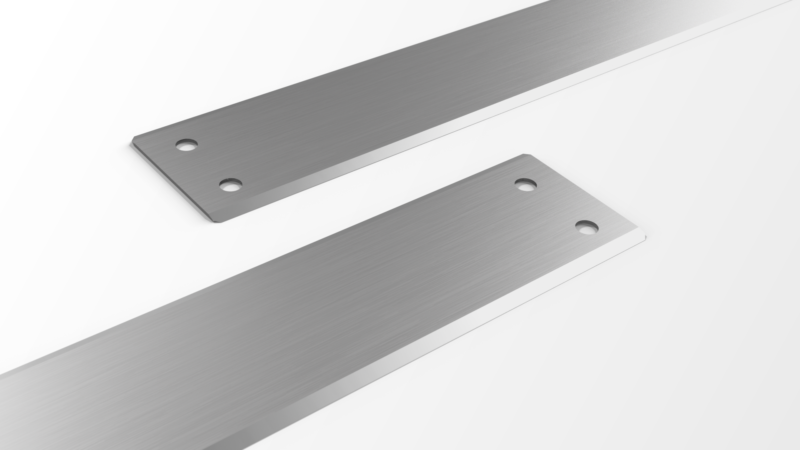

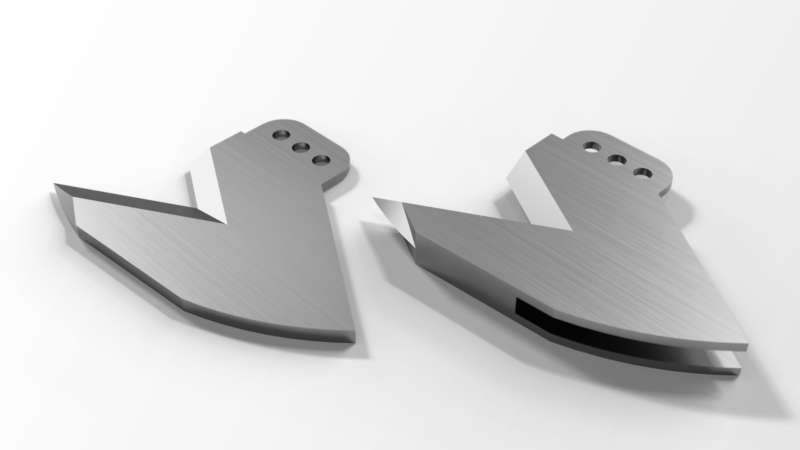

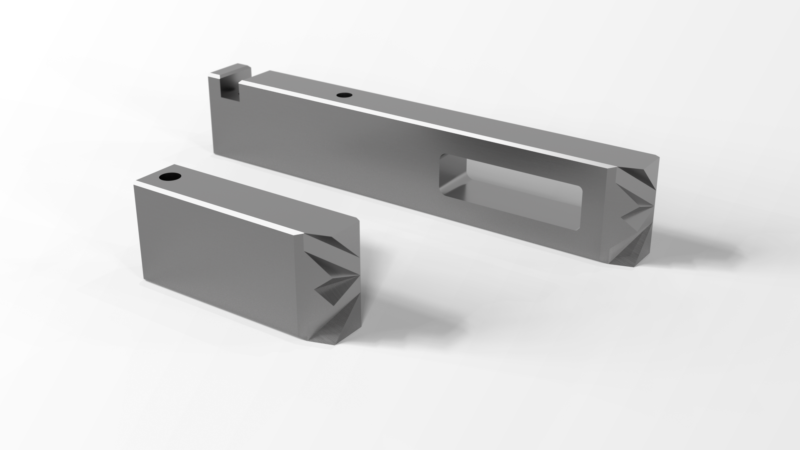

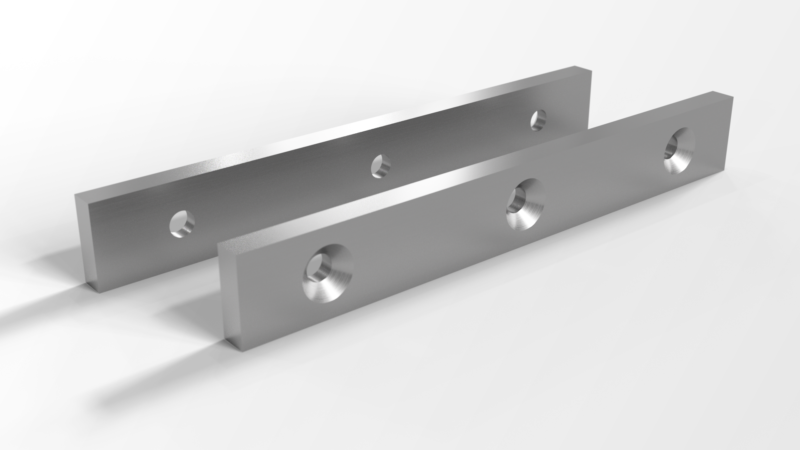

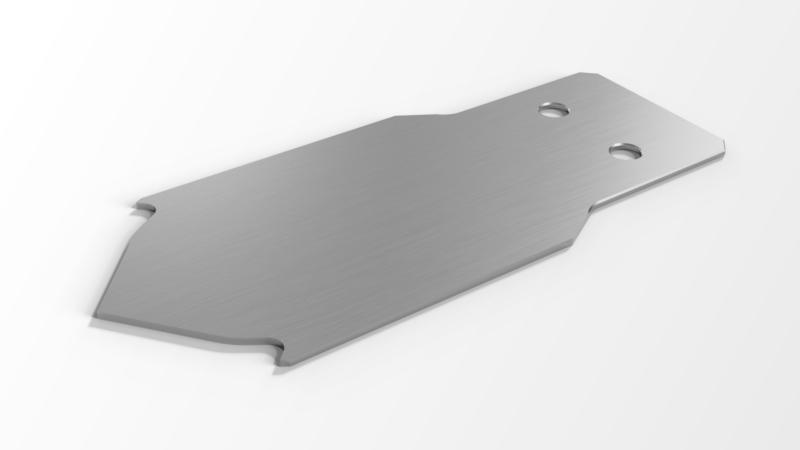

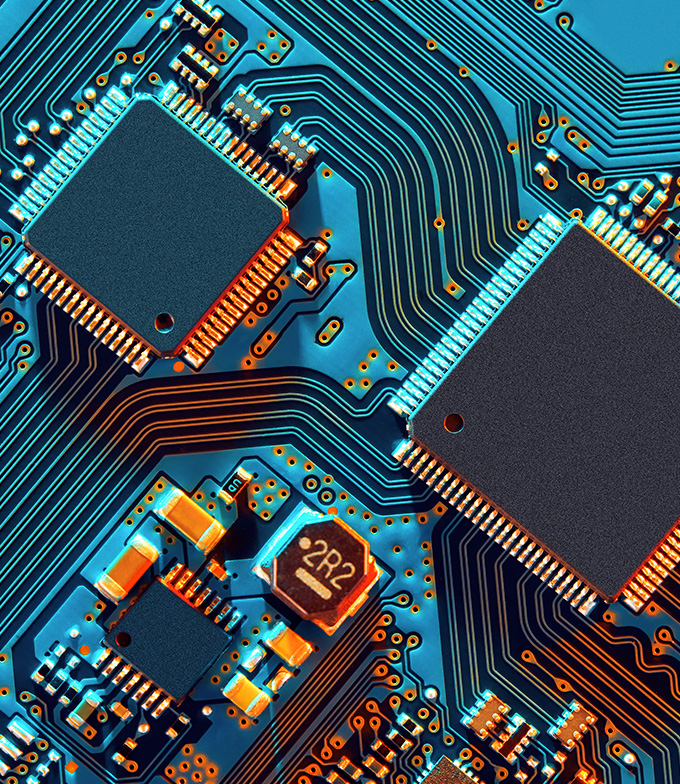

For every applicationSpecial knives are not only tailored to a specific application by name. As an industrial knife manufacturer, we know first-hand that cutting edge geometry, choice of material and coating must match the respective application. That is why we offer you a large selection of different types of knives. This gives you an optimum solution for your application. On this page we present our knife types in compact form. For a better overview, we have sorted them both by the material to be cut and by target industry.

However, we know that despite this large selection of types of ground, there are always areas of application that cannot be covered by our existing special knives. That’s why we support you as a development partner, either adapting existing knives or developing completely new special knives for you.

Wir bieten passende Maschinenmesser für alle Hersteller und Maschinentypen

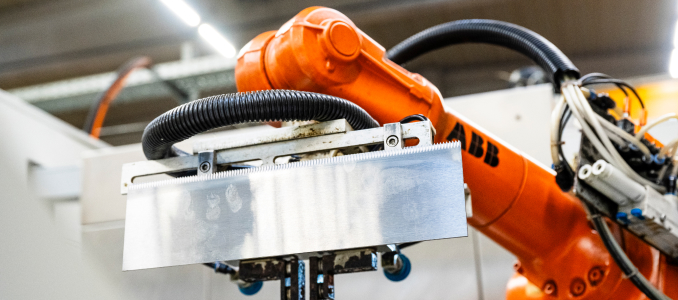

Optimale Planung – Produktion mit modernsten Maschinen – so erfüllen wir Ihre Anforderungen ohne Wenn und Aber.

Für unsere Maschinenmesser garantieren wir als OEM-Hersteller höchste Qualität und flexible Lösungen.

Als Remscheider Traditionsunternehmen produzieren wir Maschinenmesser und Co. in bereits fünfter Generation.

Types of material that can be cut

For every application

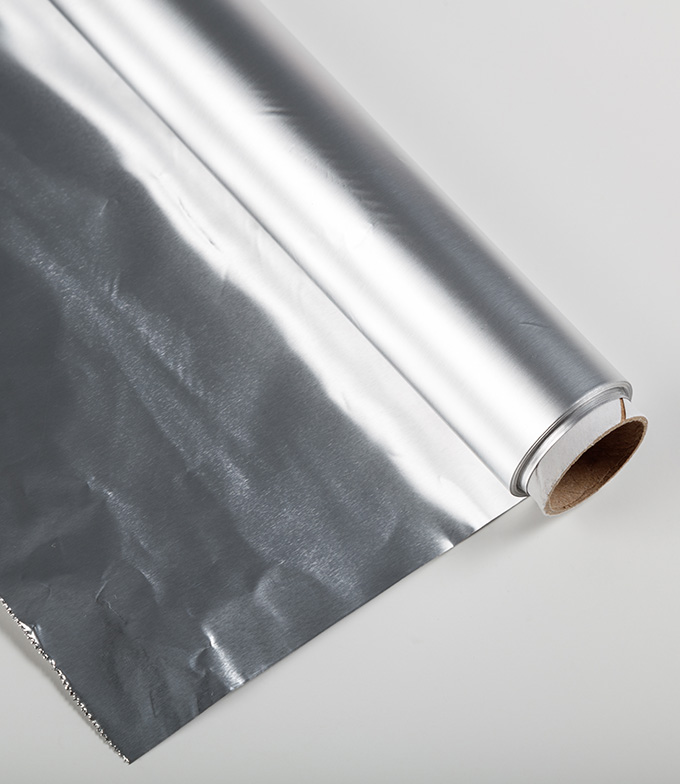

Aluminum foil

Bioplastics & alternative packaging

Composites

Fleece

Foils & Tubular Films

Food

Paper & Cardboard

Plastic

Rubber

Special material

Steel

Unser Service für Ihre Industriemesser

Your questions, our answers

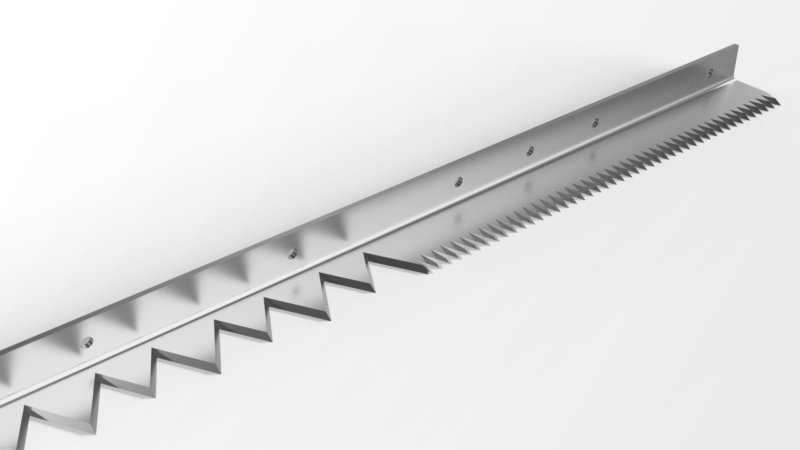

Films present different challenges when cutting than paper and cardboard, for example. In the food and pharmaceutical industries, there are also special hygiene requirements. As a manufacturer of special knives with almost 160 years of experience in various markets and target industries, we are familiar with the different areas of application and know that these also entail very different requirements.

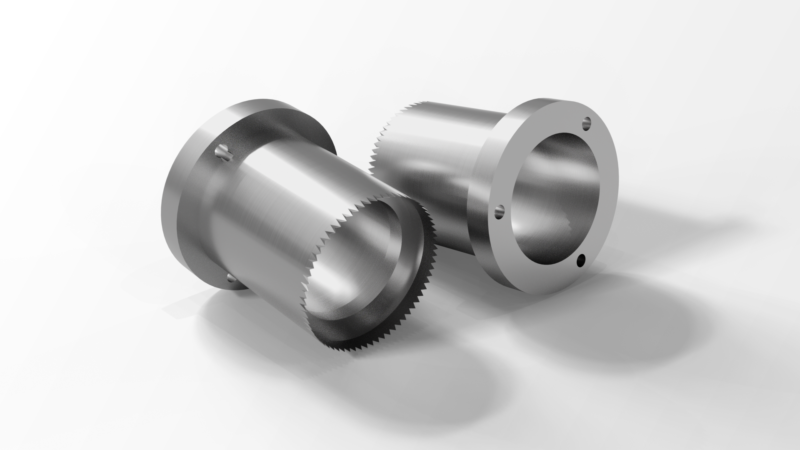

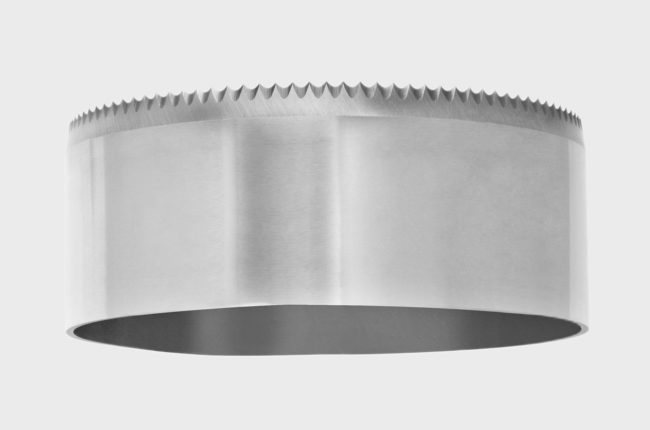

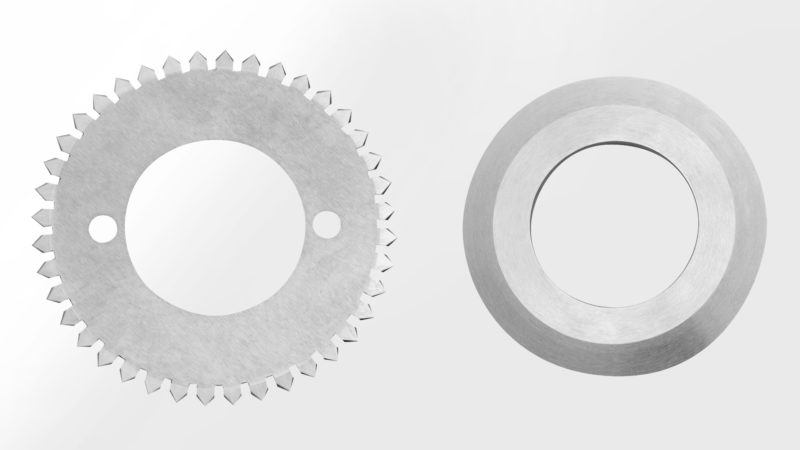

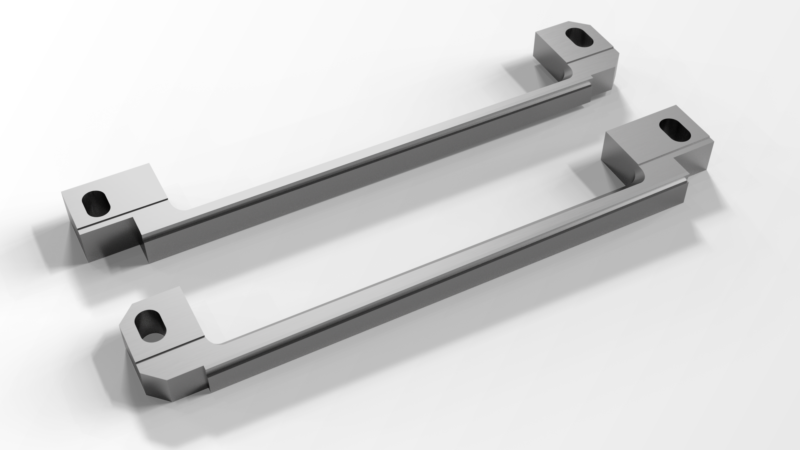

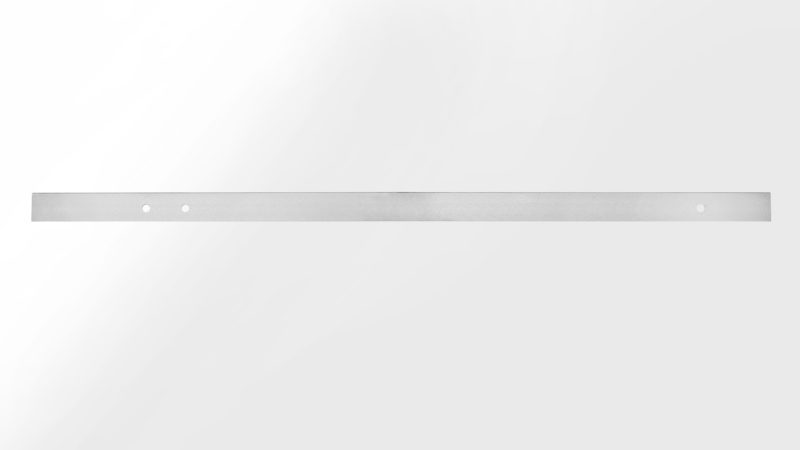

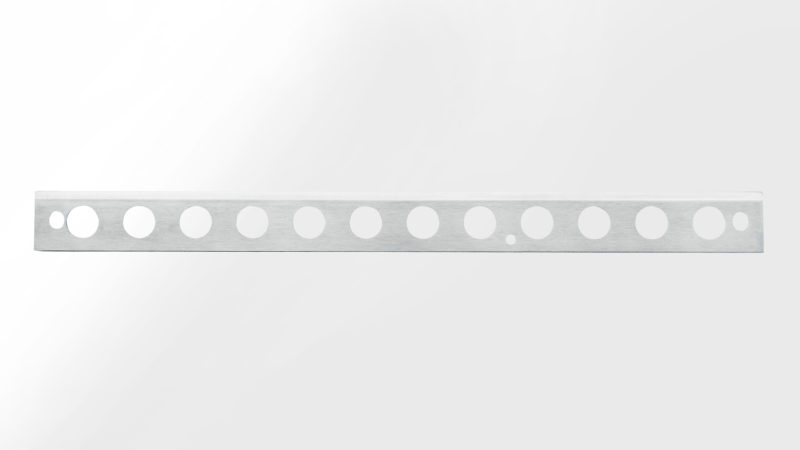

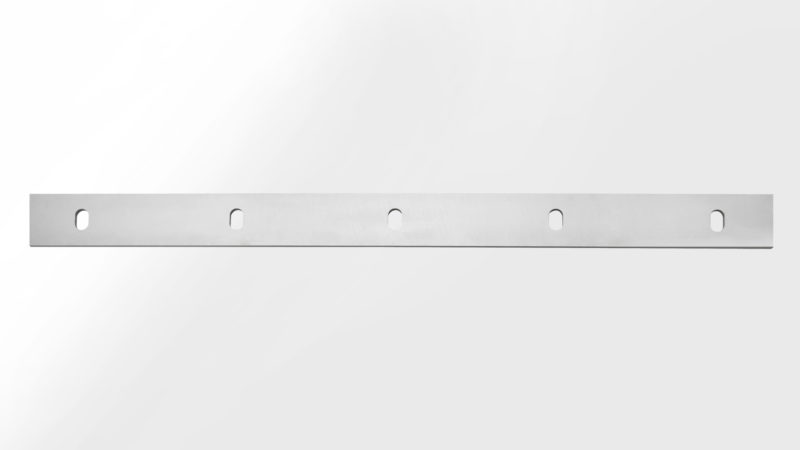

Basically, knife types can be differentiated on the basis of cutting edge geometries, material type and coating. These allow us to adapt the knives precisely to the material to be cut in order to achieve precise results and a long service life. By selecting the material, we can meet requirements such as hygiene and food compatibility. Stainless steel, for example, is particularly suitable for this. We use special coatings to ensure that no material sticks to our special knives.

The various industries and materials presented on this page will give you a good orientation. Our experts will advise you on individual properties such as the hardening process or alternative materials and optimize geometries in order to develop the optimum solution for your application.

For almost 160 years, Winterhoff Picard has stood for the highest quality and innovative spirit. Over the course of our company history, we have continuously expanded our expertise and acquired specialist knowledge for various industries. As a result, we are generally very good at identifying the needs and requirements of new fields of application. In this way, we combine experience, development expertise and innovation.

We are an experienced development partner for special knives and have the know-how to optimally cover your requirements. As part of this, our experts first conduct a consultation with you, then analyze your needs and plan a prototype, which we implement and test for functionality in practice. Only when everything fits do we move on to series production.

We will be of service to you

Your direct contact to Winterhoff Picard